Lamps are fairly simple devices, with only a few basic components. As additions to any room in a home or office they not only provide ample light, but reflect a person’s style. However, there are so many lamps and bulbs available, you may not know where to start. Here, the team at Mitronix explains the different parts of a lamp to help you choose the best one for your needs.

Light Bulb

Light fixtures use basically two types of bulbs. Either standard 120 volt (line voltage) in varying wattages, or low voltage (commonly 12 volt or 24 volt). Low voltage lamps require a transformer which is often built into the base of the fixture or elsewhere in the circuit. There are various sizes and shapes of bulbs of either type. Choosing the right type/shape depends upon many factors including:

- Electrical Constraints

- Environmental Factors

- Aesthetics

- Functional Requirements

- Local Regulations

Switch

The lamp switch is used to turn the light bulb on and off. It can be built into the lamp or separate, mounted on a wall nearby, on the lamp cord or touch-activated. Although all switches serve the same purpose of closing the circuit loop of a lamp, they come in a variety of types, including:

- Dimmer

- Pole

- Push-Button

- Twist

- Solid State (found in touch lamps)

Lamp Holder/Socket

The most important part is the lamp holder/socket. Without it, the lamp cannot perform properly. The general construction of a lamp holder includes a locking mechanism, such as threads or pins, that creates a secure connection between the lamp and the lamp holder. With a well-established link, the lamp socket powers the light bulb using its contacts and wire that connects to the electricity.

There are many different types of lamp holders and sockets to fit the different bulbs available, including:

- Bayonet-Base Lamp Holders: This socket features two pins that allow for the twisting and locking of the bulb into place.

- Compact Fluorescent Lamp Holders: CFLs must have a ballast to work. While some bulbs have an internally integrated ballast, others must have a ballast somewhere in the lighting circuit.

- Fluorescent Lamp Holders: These sockets can accommodate linear, bent, circline, and compact bulbs. They may be a single-pin or two-pin and shunted or non-shunted.

- Halogen Lamp Holders: These lamp holders are available in line voltage and low voltage versions and are made in many sizes and shapes. Round and rectangular are the most common.

- Medium-Base Lamp Holders: Also known as Edison-base lamp holders, these are some of the most widely used lamp holders and bulbs.

- Metal Halide Lamp Holders: These sockets are made with durable materials to accommodate high-intensity discharge (HID) lamps.

- Mogul-Base Lamp Holders: These sockets are made from sturdy cast porcelain that allows them to withstand the higher operating temperatures of the light bulbs used.

- Wedge-Base Lamp Holders: Designed to accept the wedge shaped bulb base with wrap around wires, these lamp holders are available in many materials and mounting styles.

Understanding the differences between lighting sockets will ensure you find the right choice in material, size, and fixture spec requirements for your residential or commercial use.

Lamp Base

The lamp body and base can take many forms. While the base serves a functional purpose (for low voltage lamps, the base holds a transformer), it also adds character to the lamp. They can be made from a variety of materials to create simple to elaborate designs.

Shade/Shade Stand

Since a light bulb can be very bright, a lampshade takes the harshness of the bare bulb and directs/diffuses it so it is comfortable and meets the light needs of the user. A shade may come as part of the lamp or a separate piece that is attached to a shade stand. Lampshades are created with a metal wire frame that holds its shape while being lightweight. Shades are available in a range of shapes, sizes, and colors to fit people’s preferences.

Fitters

A fitter is needed to connect the lampshade to the lamp. The lampshade frame will have fitter parts that extend inward to connect it to the lamp’s base.

Lamp Holders from Mitronix Inc.

Understanding the parts of a lamp will help you make a well-informed decision on one that will meet your lighting needs. As a premier supplier of lighting products for over 30 years, Mitronix offers a large selection of lamp holders and other accessories used across a wide range of industries. Contact us to learn more about our lamp sockets and other lamp parts or request a quote today.

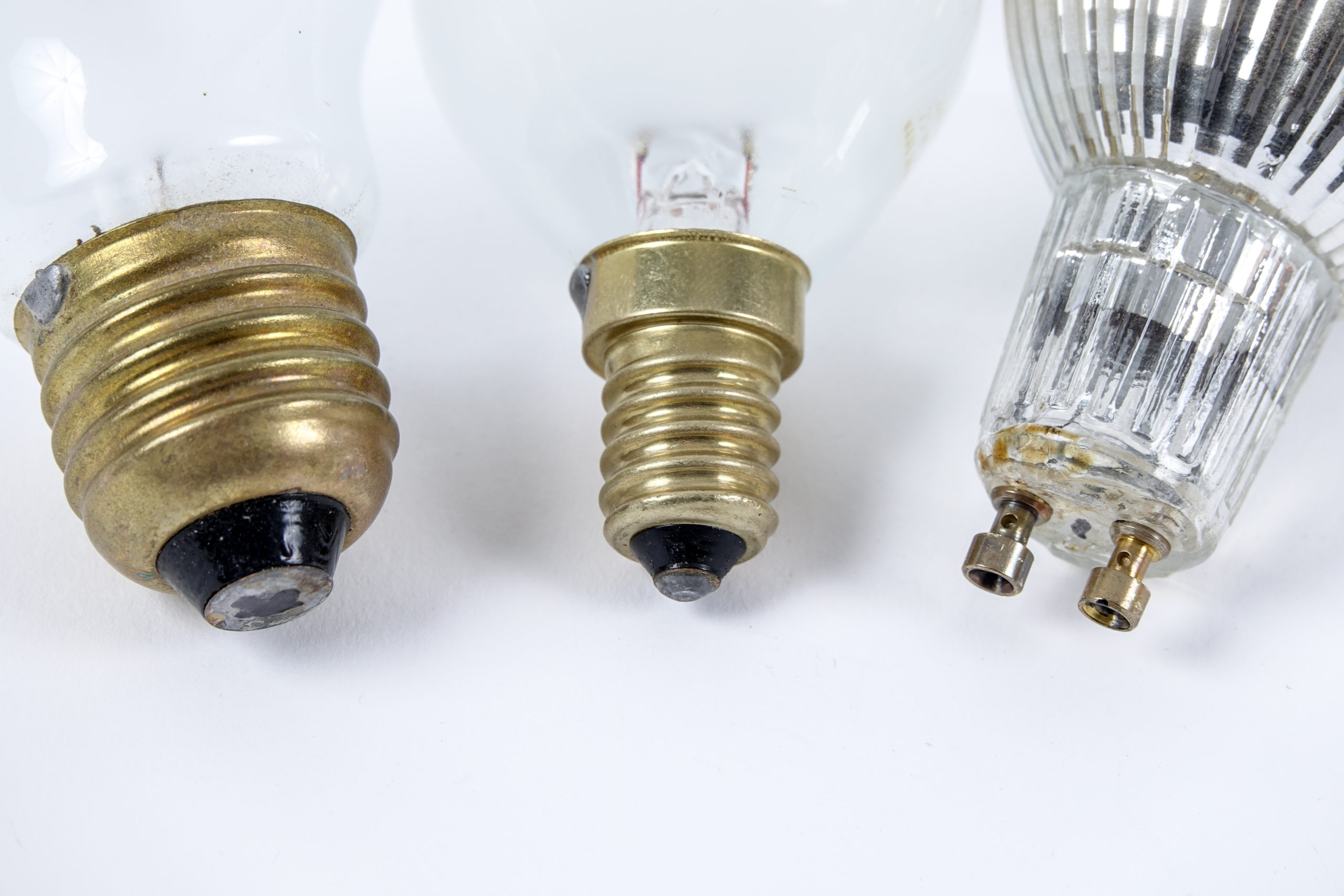

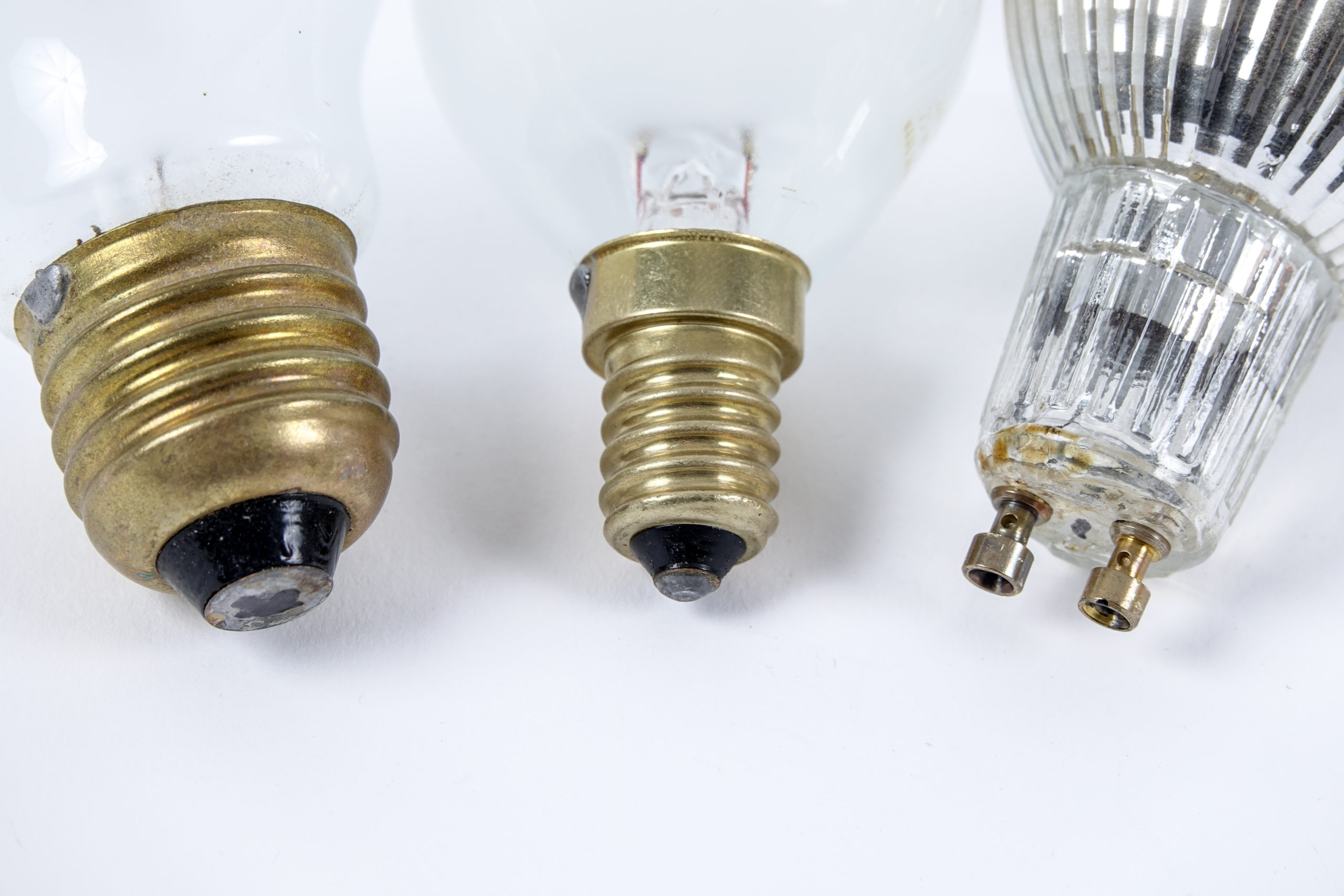

When designing lighting equipment, the selection of the proper lamp holder, also called light bulb holders or light bulb sockets is a critical step in the process. The selection of the bulb will depend on many variables such as size, lumens, energy efficiency, bulb life, etc. Once the bulb has been selected, a review of lamp holder parameters can begin. While the exact design and construction of the lamp holder vary depending on the intended bulb type and application, there is generally a locking mechanism (e.g., threads or pins) that facilitates the establishment of a secure connection between the lamp and the lamp holder.

As indicated above, lamp holders come in numerous variations, each of which is compatible with a specific bulb type. Since the bulbs can vary in design (e.g., Edison screw vs. bayonet base) and size, it is important to understand what types are suitable for use with a given lamp holder to ensure you choose the right one for your lighting system. In the following guide, we cover some of the common types of lamp sockets to help industry professionals know what to look for when designing a new fixture or purchasing a replacement lamp holder.

As suggested by the name, halogen lamp holders are designed for use with halogen lamps. Halogen bulbs are technically a variation of incandescent bulbs as they rely on the heating of a tungsten filament to produce light. However, they differ from standard incandescent bulbs in regard to the glass envelope and gas contained within the envelope. These design differences result in greater brightness, longer service lives (for the bulbs), and hotter operating temperatures. For these reasons, they are often used in a variety of commercial (e.g., retail and jewelry stores) and residential (e.g., home lighting) applications. They are also integrated into specialty products, such as projectors and food heaters.

The lamp holders for these bulbs vary depending on the intended bulb. They can be designed to accommodate a variety of bulb sizes and feature different design elements, such as dedicated (G4) lamp holders or multi-base ((G4, G5.3, G6.35) lamp holders round or rectangular construction. They are also available in threaded versions (E11), recessed single contact (R7s) and twist-lock (GU10).

Visit this page to find out more about the halogen lamp holder offerings from Mitronix.

Metal halide lamps are a form of high-intensity discharge (HID) lamps that offer efficiency ratings that are up to three to five times greater than that of incandescent lamps. They rely on the passing of electrical current through a specialized gaseous mixture—typically consisting of mercury, xenon/argon, and metal halides—to produce light. The intensity of the light produced necessitates the use of durable materials for the construction of the lamp and lamp holder. This requirement is further exacerbated by the typical use cases of metal halide lamps—i.e., the illumination of outdoor environments such as streets, parking lots, and sports arenas.

Visit this page to find out more about our metal halide lamp holder offerings.

Medium-base lamp holders—also referred to as Edison-base lamp holders—accommodate a variety of screw-base bulb types. While screw-base bulbs are available in several sizes, the medium-base ones are E26 (MES in North America) and E27 (ES in Europe). The E standards for Edison (the inventor of the screw-base bulbs) and the following number indicates the width of the bulb’s based in millimeters. As the difference between the base sizes of these bulbs is one millimeter, the bulbs can be used interchangeably within a single lamp holder.

Screw-base bulbs also vary in regard to the bulb shape. Some of the most common include A-shaped (e.g., A15, A19, and A21), globe-shaped (e.g., G16.5, G25, and G30), PAR (e.g., PAR16, PAR20, and PAR30), and bulged reflector (e.g., BR20, BR30, and BR40).

These lamps and lamp holders are used for general commercial and residential lighting applications, such as for can lights, ceiling lights, floodlights, spotlights, and vanity lights.

Visit this page to find out more about our medium-base (E26) lamp holder offerings.

Mogul-base lamp holders are used for mogul-base lamps (E39), which have a much larger screw-base size than medium-base lamps (E26/E27). As they are often used in street lighting and other high-wattage lighting systems, they are made from sturdy cast porcelain to accommodate the higher operating temperatures. Any bulb that includes “U” in the product description (e.g., M175/U/MED) requires a mogul base. However, using an adapter allows the mogul base to accommodate smaller bulbs (e.g., E26).

Visit this page to find out more about our mogul-base (E39) lamp holder offerings.

Fluorescent lamp holders are designed for use with fluorescent bulbs, which are known for their high energy efficiency (compared to incandescent and halogen bulbs) and low cost (compared to LEDs). They can accommodate linear, bent, circline, and compact bulbs with single-pin or two-pin and shunted or non-shunted socket designs. Typical applications include retail stores, offices, and schools.

Fluorescent lighting systems require ballasts, which regulate the flow of electricity to prevent the lamp from drawing too much current. Shunted sockets allow for electricity to flow along multiple paths, while non-shunted sockets only permit current flow through a single path. The former is used for instant-start ballasts while the latter utilized for dimming ballasts.

Visit this page to find out more about our fluorescent lamp holder offerings.

Compact fluorescent lamps (CFLs) are a specialized type of fluorescent lamp that resembles medium-base light bulbs in size and base. Since they function similarly to standard fluorescent lamps, they are generally more energy-efficient than conventional incandescent bulbs. Some examples of typical applications include hospitality and residential settings.

Similar to all fluorescent lamps, CFLs require a ballast to work. Integrated CFLs rely on an internally integrated ballast, while non-integrated CFLs employ a ballast integrated into the lamp holder. The former is cheaper and simpler, while the latter is longer-lasting and easier to replace.

Visit this page to find out more about our compact fluorescent lamp holder offerings.

Bayonet-base lamp holders accommodate bayonet-base lamps. These bulbs—sometimes called twist and lock bulbs—feature two pins to facilitate twisting and locking the bulb into place.

Bayonet-base bulbs were used in the automotive industry for many years due to their ruggedness and ease of replacement. They have been replaced by LED’s. They are either single or double contact to match single (BA15S) bulb base or double (BA15D) bulb base. There are also miniature bayonet bulbs and sockets. Bayonet- base bulbs are preferred in many applications where vibration is a concern and can be used with the bulb upside down with no fear of it falling out.

Visit this page to find out more about our bayonet-base lamp holder offerings.

Wedge-base lamp holders are generally used for smaller low wattage light bulbs, such as those found in string lights. The lamp holder socket allows for contact between the lamp holder contacts and the exposed wires of the wedge-shaped bulb base. This design enables users to replace bulbs quickly and easily. They are available with many mounting options like brackets, PCB tabs, snap-in and twist-in. There is also a subminiature version.

Visit this page to find out more about our wedge-base lamp holder offerings.

When converting a fixture from one lamp holder base to another, usually to replace a less efficient bulb to a more efficient bulb, the simplest way is to use an adaptor. This is an economical solution using adaptors and reducers to modify the lamp holders to be compatible with the new bulb types. These devices allow larger bulbs to fit into smaller bases and/or different base types to fit into different sockets. Energy saving is one of the major reasons that adaptors are used. Converting from an E26 Edison bulb to a GU24 compact fluorescent can save 50%. Also, simply changing from a larger bulb (E26) to a smaller bulb (E14) saves energy. Adaptors make these changes simple.

Visit this page to find out more about our adaptor and reducer offerings.

Contact Mitronix, Inc. Today for Your Lamp Holder Needs

At Mitronix, we have served as a premier supplier of lighting products for over 30 years. We offer a broad selection of lamp holders and other lighting system accessories to meet the lighting needs of customers across a wide range of industries. For additional information about our product offerings or pricing estimates for a specific product, contact us or request a quote today.

(Click to Expand)

(Click to Expand)

Most people don’t realize that they may have the wrong type of socket in the fixture they are looking to change over from a fluorescent bulb to an LED bulb. Using the wrong socket can cause an electrical short, melt components or potentially start a fire. The socket, also called a lamp-holder, or tombstone come in two types -Shunted and Non-Shunted -each is designed for a specific bulb/socket/ ballast circuit.

Shunted and Non-Shunted Sockets

The main difference between sockets is the way the electrical currents flow through the ballast, a part in the socket circuit that regulates the electric current and provides voltage to the lamp.

- Shunted sockets receive electricity through a single point and spread it to two points of contacts. There is one path in a shunted lamp holder, and the current only flows one way.

- In a non-shunted socket,on the other hand, the voltage is received on every point of contact, and the current flows through multiple paths. The contacts aren’t connected.

How to Identify a Shunted or Non-Shunted Sockets

In a shunted socket, the contacts are connected inside the socket, which creates a continuous arc between both electrodes. A non-shunted socket is just the opposite. There isn’t continuity in a non-shunted socket because there aren’t any internal connections between contacts.

To identify a socket type, you need to use a voltage meter and test the contacts for continuity. Continuity is the complete path of an electrical current.

Set your voltage meter to “continuity” and touch one probe to a neutral or ground contact and the other probe to a hot wire, screw terminal, or outlet slot. If the meter beeps, rings, lights up, or issues another alert, it means you have a shunted socket.

In some cases, you might also be able to check if a socket is shunted or non-shunted by counting the number of holes in the socket. Shunted sockets usually have two holes, and non-shunted models have four. However, these numbers can vary, and it’s always safest to verify the type with a voltage meter. Follow the specific instructions on your voltage meter to be sure of its accuracy.

What Is a Ballast?

Some lighting fixtures need a ballast to operate. The ballast is part of the circuit that alters the amount of energy that’s transferred into the light fixture. When you first switch on a light, the ballast releases a high-energy voltage to establish an arc between contact points. After the connection is made and the light turns on, the ballast restricts the energy output to keep the bulb from overheating and burning out. They can also help to limit the fixture’s overall energy expenditure and are an important element for cost- and energy-efficiency.

A ballast is the functional part of a fluorescent light source. Just as a heart regulates blood flow to your body, a ballast ensures that a light bulb stays lit by managing the distribution of energy throughout the fixture. Hearts work to distribute blood via channels or arteries in the body to keep it active and alive. Similarly, ballasts have the same responsibility for fluorescents, but with energy.

There are several different types of ballasts available, which determine how quickly the light turns on and if the user can control the brightness in the room by degrees with a dimmer or program setting.

Here are a few popular ballast options:

- Instant-start

- Dimming

- Pre-heat

- Program start

- Rapid start

- Trigger

In general, an instant-start ballast can only be used with a shunted socket. Non-shunted sockets can be used with dimming, pre-heat, program start, rapid start, and trigger ballasts.

Contact Mitronix for All of Your Non-Shunted Socket Needs

At Mitronix, we specialize in supplying sockets for a variety of lighting solutions. We understand that homeowners, manufacturers, and commercial properties have diverse needs and exact specifications, which is why we’re here to help. When your requirements call for non-shunted sockets or any other type of sockets, Mitronix is the industry-leading supplier you want for all of your socket needs. Contact us to speak with one of our team members today.

(Click to View)

(Click to View)

(Click to Expand)

(Click to Expand)